Casting Workshop

Laser Engraving

- High precision (up to ±0.1mm tolerance)

- Capable of processing complex 3D geometries

- Clean and environmentally friendly with minimal material waste

- Digitally controlled with excellent repeatability

Laser Cutting

- High-Precision 2D Cutting

- High Speed & Superior Edge Quality

- Tool-Free Manufacturing

Model Assembly Process

- Bond multiple foam model components into an integrated structure

- Install the gating and riser system

Coating Application

- Apply refractory coatings to the model surface

- The coating possesses adequate strength and permeability

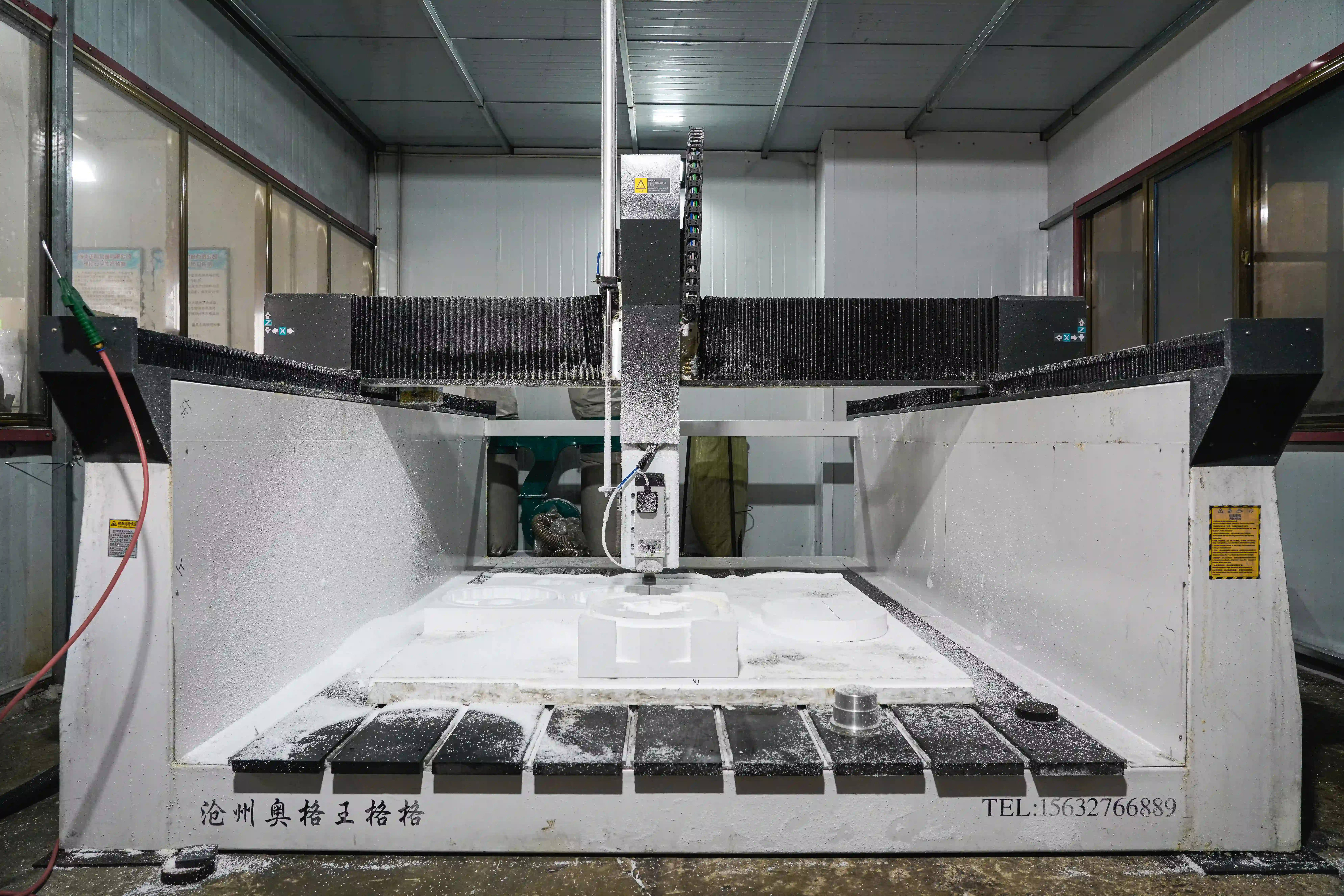

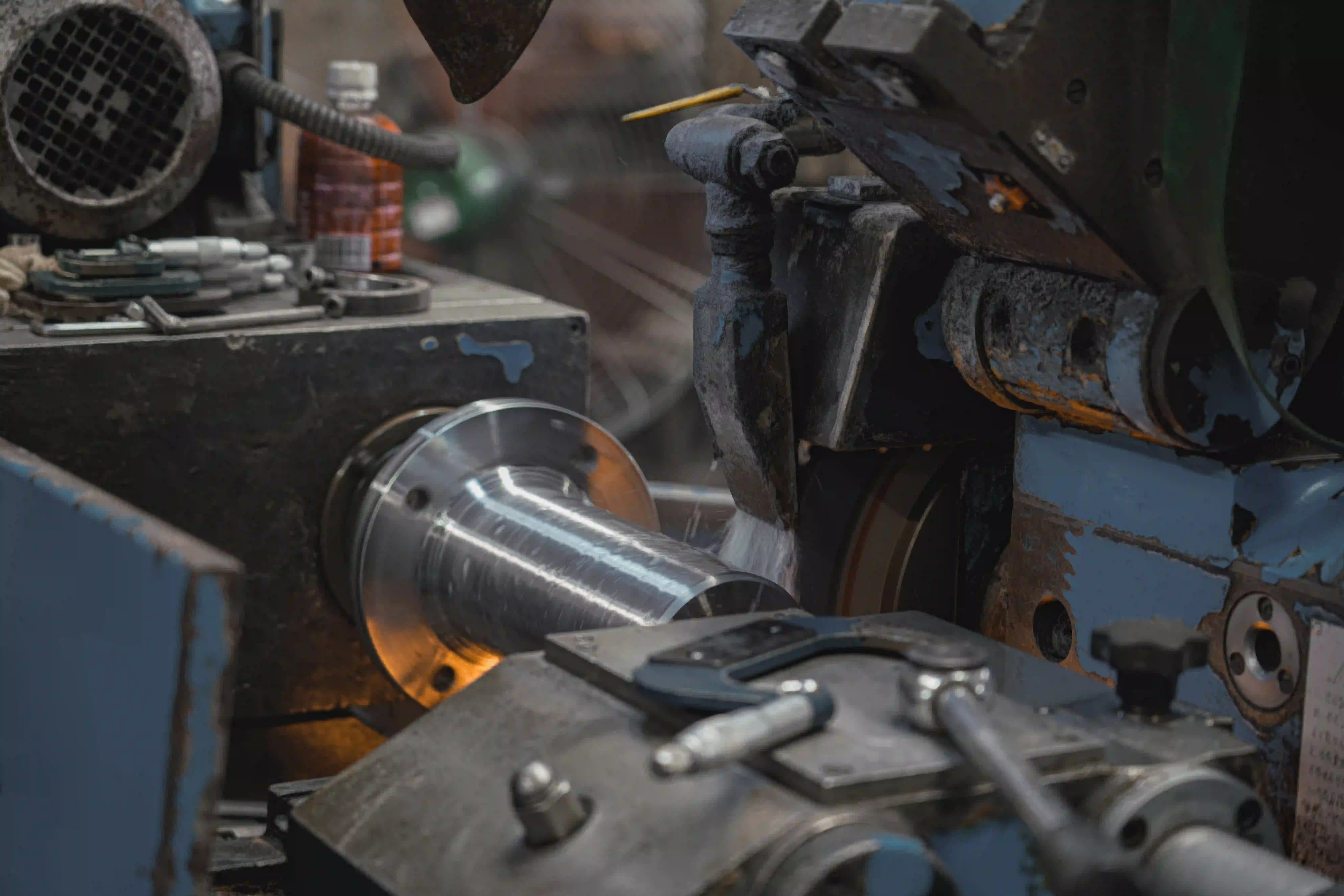

Machining Workshop

Large-Diameter Pulley

- Dimensional Stability Control

- High-Precision Groove Machining

- Dynamic Balancing Assurance

Cylindrical Grinding

- Stepped Shafts

- Tapered Surfaces

- Camshaft Grinding

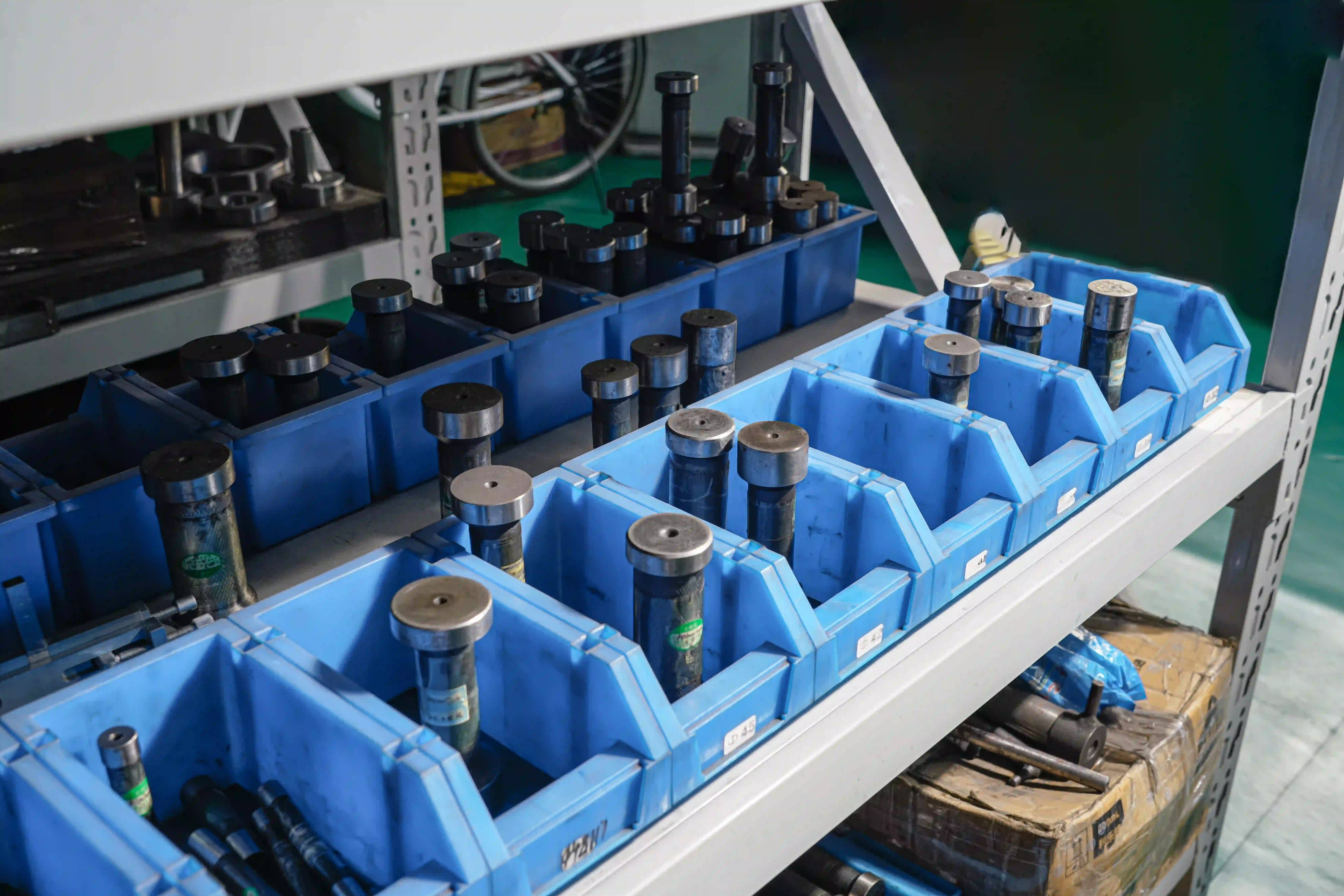

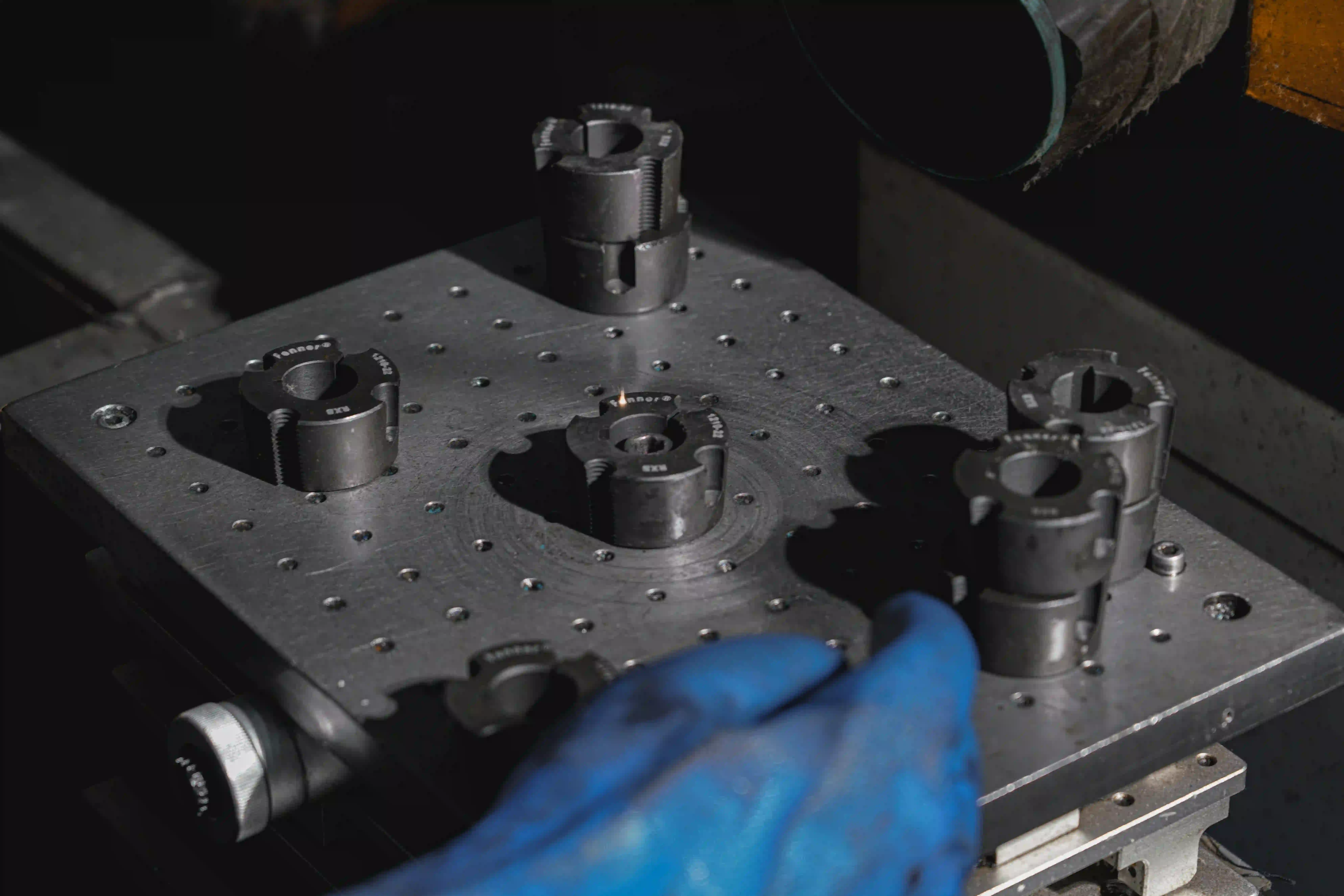

ATC Machining Center

- Fast tool change, high-capacity tool magazine

- High-efficiency continuous machining

- Ultra-high precision assurance

Surface Treatment Workshop

- Pretreatment Zone: Remove oxide scale/oil contamination, enhance adhesion

- Spraying Zone: Primer → Base coat → Clear coat

- Inspection Zone: Compliant with ISO 4525/ASTM B117

Inspection Workshop

- Geometric

Inspection:

- Raceway roundness (measured by roundness tester)

- Groove pitch deviation (measured by pneumatic gauge)

- Performance

Testing:

- Endurance test

- Abnormal noise inspection

- Data

Traceability:

- Generate M2QR code (containing complete inspection data)

Packaging Workshop

Laser Marking

- Production Date/Batch Number

- Safety Warning/Brand Marking

Warehouse Packing & Boxing

- Order Picking

- Cushioning

- Case Erecting

- Sealing

EN

EN

中文

中文